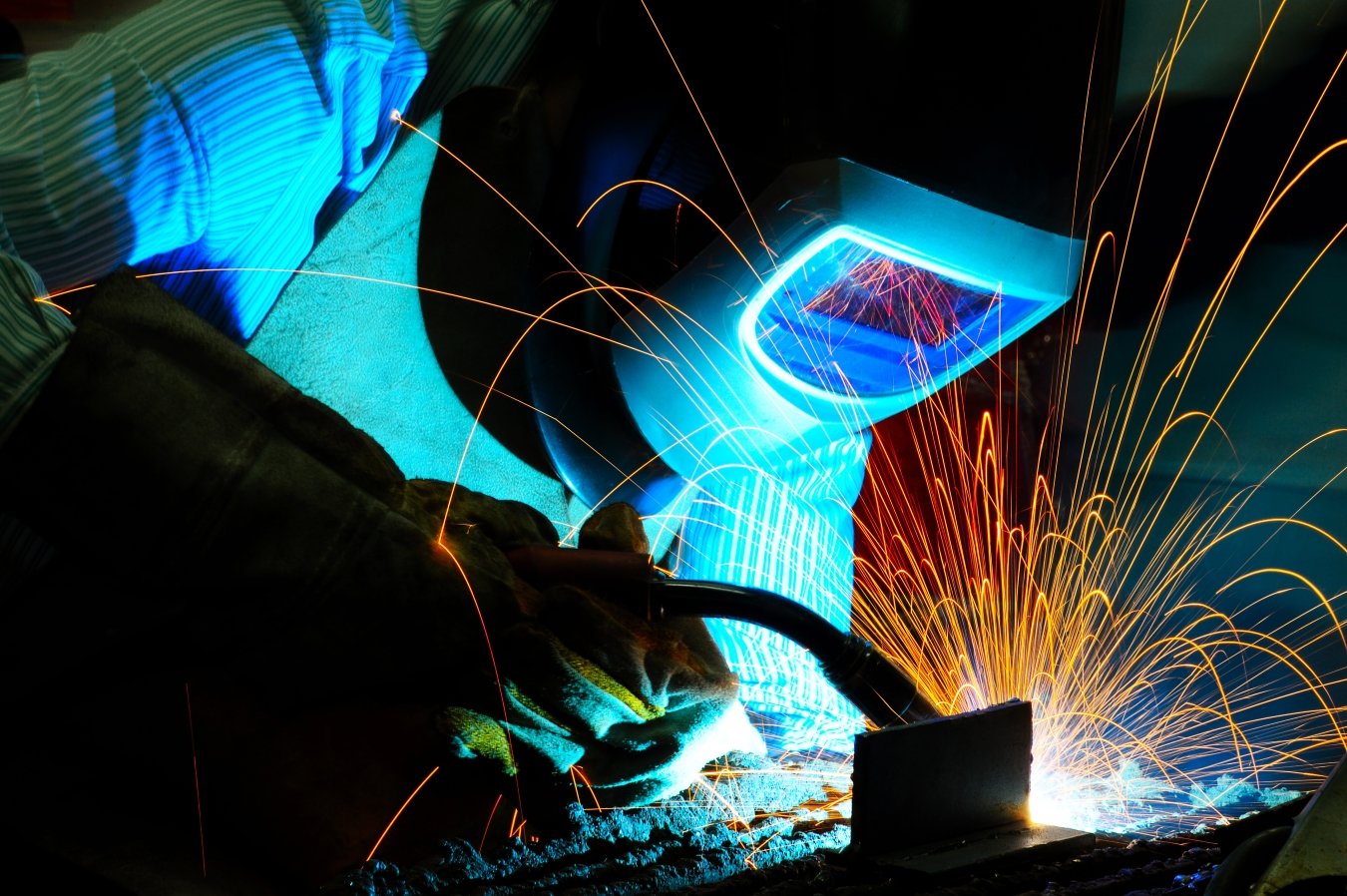

About Metal Inert Gas (MIG)/Metal Active Gas (MAG) Welding Training

The aim of the course is to enable delegates to produce welds in flat and horizontal/vertical positions to a standard, safely within a reasonable time frame. More able delegates will try out of position welding such as vertical up and overhead.

Is it right for me?

The courses can be tailored to suit novices or more experienced welders looking to upskill or recode as well as being engineered to meet the employer’s needs.

What will I learn?

The candidate will demonstrate his/her ability to:

Set up the welding equipment to include changing wire and gas, voltage/wire speed selection, additional settings dependent on machine type

Consumable selection such as electrode wire classification and types, gas selection and contact tips.

Health and safety relating to the welding processes

Produce basic welds in the workshop to include Beads on plate, T and lap fillet welds, butt welds and open corner welds on 2mm-5mm sheet/plate

Welding theory to include: MIG/MAG, distortion control, weld symbols, gas cylinders, weld defects, weld testing and health and safety

Make safe and effective repairs

Operate within the HASAWA 1974

Use appropriate Personal Protective Equipment (PPE) to include safe use of welding masks/air fed masks

The benefits?

The course will raise the delegates’ skill level by the use of practical welding with lectures on:

Using the equipment safely and changing parts of the system

Relevant parts of Control of Substances Hazardous to Health regulations (COSHH)

Personal Protective Equipment (PPE)

Process applications

Basic machine maintenance

All practical welding and instruction takes place at the bench maximising the time for practical work.

Evaluation Method - Test pieces produced during the course and assessed by the trainer.

For more information on this course, please contact MCP on 0121 506 9030 or email [email protected]