Logical Approach to Fault Finding and Root Cause Analysis

Why Your Downtime Feels Like Déjà Vu

(and How to Break the Cycle)

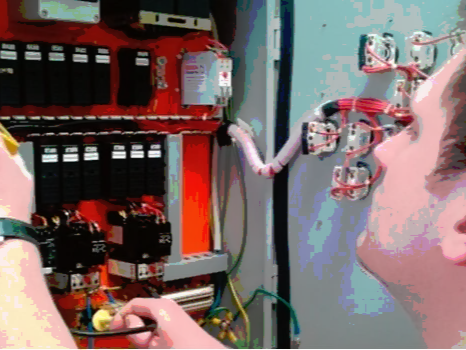

Ever noticed how some breakdowns keep coming back like bad reality TV spin-offs? Same fault, same fix, same frustrated sigh from the maintenance team. Maybe someone gives it a thump, mutters something unprintable, and — miracle! — the line’s running again. Until it isn’t.

That’s because bodging and scarpering is not a maintenance strategy (though it can be oddly therapeutic). What your team really needs is a logical approach to fault finding and root cause analysis.

The Cost of Getting It Wrong

Here’s the unfunny bit. On average, downtime can cost manufacturers around £1,000 an hour. Some food manufacturers have seen annual losses run into the millions from unresolved failures. And yet, many technicians don’t know how much an hour’s downtime really costs their business. Imagine how different their approach might be if they did.

The Tools in the Toolbox

When it comes to fault finding on complex systems, do your technicians do anything but swap components and hope?

The best teams use structured tools and methods such as:

Half-split technique

narrowing the problem by halving the system each time.

have you asked the operator?

Condition Based Maintenance

spotting problems before they turn into crises

Input/output testing

confirming whether the fault lies before or inside the system

CMMS data

if you’ve got it, use it.

5 Whys & Fishbone diagrams

asking “Why?” until you finally get an answer that doesn’t involve “because it broke.”

Flow charts, tree diagrams & ladder logic

because drawing it out often reveals what staring won’t.

These are the tools that separate firefighting from fault finding.

Questions Worth Asking

If downtime lasts more than an hour, is a root cause analysis triggered?

Does your team know how to distinguish between symptoms and faults?

Do your technicians understand how much an hour of downtime really costs the business — and would it change their approach if they did?

Here’s the kicker: when one food manufacturer put structured RCA into practice, they cut downtime by 25% and unlocked an extra £3.75m in production output. That’s the power of asking (and answering) the right questions.

"If you don’t ask the right questions, you don’t get the right answers." – Peter Gagg, MCP CEO

Want to dive deeper? Download the ‘Get to the Root Cause’ article on ConnectingIndustry.com and hear directly from our CEO, Peter Gagg, on the topic.

How MCP Can Help

At MCP, we’ve been helping maintenance teams swap bodges for brains for over 20 years. Our Logical Approach to Fault Finding & Root Cause Analysis course gives technicians a full set of troubleshooting tools. Pair it with our Mechanical Maintenance Skills (Part 1) course, and you’ll have a team who can not only diagnose faults but fix them properly the first time.

If downtime is giving you headaches, we can help.

Prices Quoted Exclude VAT

Course Type | Mechanical, Technical Skills

Certificate | MCP Training Certificate

Duration of Course | 4 Days

Location | Reading